Advanced Analysis of Optical Coatings Using OSLO and TracePro

Optical coatings have transformed modern optics, playing a pivotal role in defining how light interacts with surfaces. From increasing transmission in camera lenses to reducing laser reflections in high-precision instruments, coatings determine performance at every level. However, as systems become more complex, basic evaluation methods are no longer sufficient. This is where advanced simulation tools come in—specifically, OSLO and TracePro, two of the most powerful optical software packages available.

Together, these tools enable engineers and researchers to design, simulate, and refine coating performance with an extraordinary degree of accuracy. In this article, we dive deep into how OSLO and TracePro can be used to analyze optical coatings beyond traditional methods, optimizing not just design efficiency, but real-world results.

Why Advanced Coating Analysis Is Essential

Today's optical applications often operate in high-stress environments—UV lasers, thermal sensors, or outdoor imaging systems. Traditional coating analysis falls short for several critical reasons:

- Multi-layer complexity: Coatings are sensitive to angle, wavelength, and polarization variations that simple models cannot accurately predict.

- Environmental factors: Temperature and humidity conditions affect coating longevity and function in ways that require sophisticated modeling.

- System-level interactions: Stray light, ghosting, and absorption can degrade system performance if not predicted and corrected during the design phase.

- Manufacturing considerations: Real-world variations in coating thickness and material properties need to be accounted for in design optimization.

Advanced tools like OSLO and TracePro allow for simulation under these real-world variables, enabling designers to predict and solve coating-related issues before physical prototyping. This capability is crucial in modern optical design where performance requirements are increasingly stringent and manufacturing costs must be minimized.

Overview of OSLO and TracePro

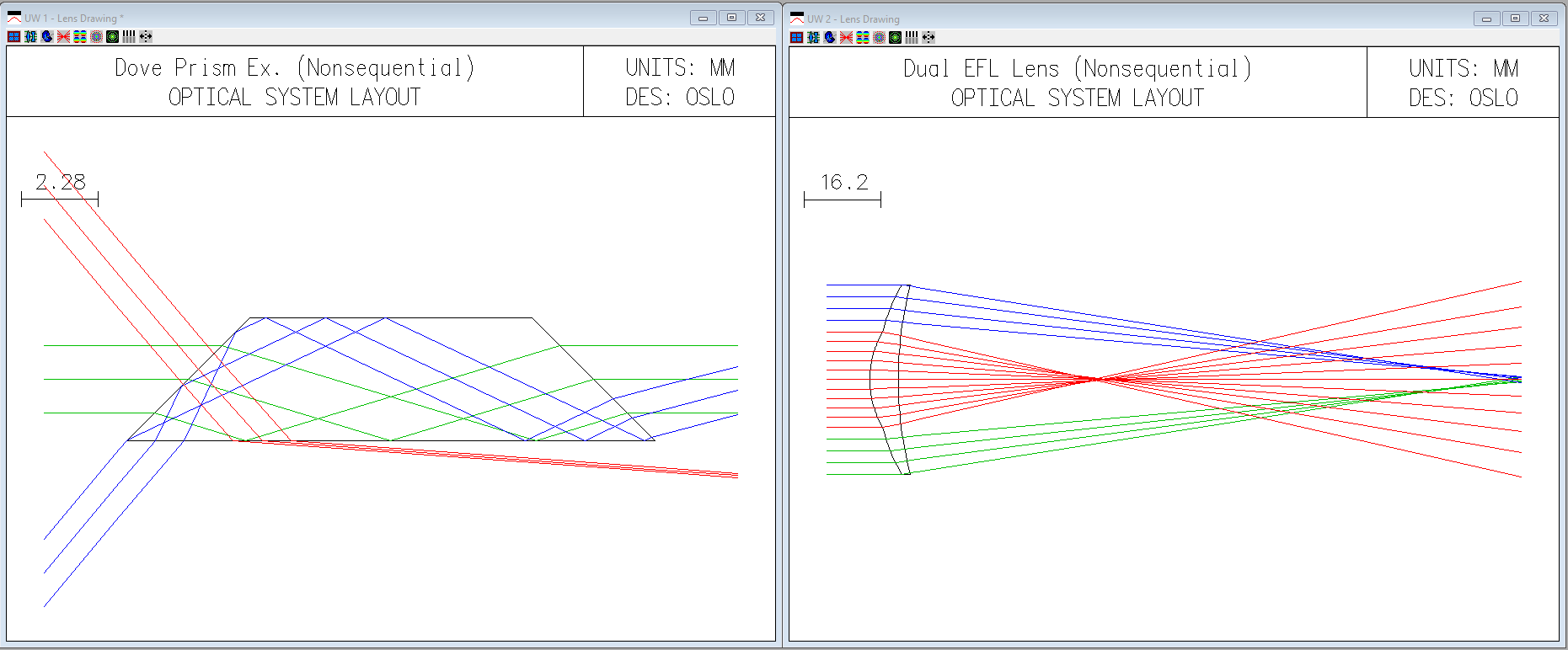

OSLO (Optics Software for Layout and Optimization) focuses on sequential optical design, making it ideal for lens systems and imaging paths. It excels in geometric layout, aberration analysis, and surface optimization. The software's strength lies in its ability to model light paths that follow predetermined sequences through optical systems.

TracePro, on the other hand, is built for non-sequential ray tracing. It's ideal for illumination systems, light guides, and evaluating light scattering and absorption. TracePro's non-sequential approach allows rays to reflect, refract, or scatter in any direction, making it perfect for complex real-world scenarios.

Together, they cover both ends of the optical analysis spectrum—precise imaging and real-world light behavior. This complementary relationship makes them invaluable when used in combination for comprehensive coating analysis.

Modeling Thin-Film Coatings in OSLO

In OSLO, users can define custom coatings or use built-in libraries for standard AR (anti-reflection) and HR (high-reflectance) types. Coatings are specified by layer thickness and refractive index, with OSLO calculating spectral performance based on interference principles. Users can simulate behavior across incident angles and wavelengths, making OSLO ideal for modeling coating stacks in lenses, mirrors, or prisms during early design phases.

The software's sequential ray tracing approach excels at modeling how coatings behave in traditional imaging systems where light follows predictable paths. OSLO's optimization routines can automatically adjust coating parameters to meet specific performance targets, significantly reducing design time while improving results.

Using TracePro for Realistic Coating Behavior

TracePro applies coatings to CAD-based geometry and simulates their real-world performance. Ray paths are analyzed for reflection, transmission, and absorption, with coatings modeled with angular and spectral dependency. While TracePro does not offer thin-film stack design tools internally, it allows users to import coating data—such as measured or computed reflectance and transmittance curves—and apply them to surfaces within the model.

This makes TracePro indispensable when precise light control or energy efficiency is crucial—such as in automotive lighting or surgical headlamps. The software's ability to handle complex geometries and multiple light interactions provides insights that sequential modeling cannot achieve.

Comparing Sequential and Non-Sequential Simulations

The key distinction is that OSLO uses sequential ray tracing, where rays follow a specific path from surface to surface, perfect for optimizing lens systems. TracePro uses non-sequential tracing, where rays can reflect, refract, or scatter in any direction. This is critical when evaluating how coatings behave in complex systems like HUDs or fiber optics, where light doesn't always behave predictably.

Using both approaches provides a comprehensive understanding of coating performance. Sequential analysis ensures optimal performance in designed light paths, while non-sequential analysis reveals how coatings handle unexpected or scattered light interactions.

Analyzing Angular Dependence and Polarization

Many coatings perform differently depending on the angle of light incidence and polarization type (s- or p-polarized). In OSLO, you can sweep through incidence angles to study reflectivity changes, with polarization states factored into coating design—especially important in laser optics.

In TracePro, polarization effects are supported with approximations, simulating interactions at interfaces and coating surfaces, although TracePro does not currently provide full vector polarization modeling. Multiple incident angles from diffuse sources can be analyzed in parallel. These tools together allow for more robust and versatile coating evaluation, ensuring performance across all operating conditions.

Optimizing Multilayer Coating Stacks

Multilayer coatings can be highly sensitive to thickness variations and material choices. OSLO allows definition of dozens of layers with fine control over each, plus built-in optimization routines to adjust layer thicknesses for target performance. This feature is vital in narrowband filters or notch filters, where even nanometer-level deviations can result in performance loss.

TracePro complements this by testing the coating in 3D geometry to ensure it behaves as expected in a system, not just on a flat test surface. Users typically import reflectance/transmittance data derived externally rather than defining stacks within TracePro. This combination ensures that optimized coatings perform correctly in their intended applications.

Heat and Absorption Effects in Coatings

While optical performance is key, coatings also contribute to thermal load in high-power systems. Improperly designed coatings may absorb light and overheat. In TracePro, absorbed power in each coating layer can be measured, with irradiance maps showing where thermal hotspots may form.

This capability is critical for applications like solar concentrators or high-intensity illumination devices, where durability is as important as efficiency. Understanding thermal effects prevents coating failure and ensures long-term system reliability.

Stray Light and Ghost Imaging Detection

One of the most important real-world issues caused by coatings is ghost imaging and stray light. TracePro tracks rays bouncing multiple times through coated surfaces, revealing unexpected reflections due to coating mismatches or geometry flaws.

While OSLO can detect ghost foci and parasitic images during lens design, TracePro's visualization tools—like ray density plots and scatter diagrams—make it easier to pinpoint and eliminate these artifacts before manufacturing. This capability is essential for high-quality imaging systems.

Integrating OSLO and TracePro in Design Workflow

To get the best of both worlds, a systematic workflow approach maximizes the strengths of each platform:

- Initial design phase: Use OSLO to layout lens or mirror systems, define coating specifications, and optimize for target transmission/reflection performance using sequential ray tracing.

- Geometry transfer: Export optimized designs to TracePro for comprehensive non-sequential analysis and coating interaction modeling in realistic 3D environments.

- Performance evaluation: Analyze thermal load distribution, scattering effects, and performance under non-ideal conditions including manufacturing tolerances and environmental variations.

- Iterative refinement: Return to OSLO for fine-tuning based on TracePro results, then re-test in TracePro to validate improvements and ensure optimal performance.

This iterative loop ensures coating success from design to deployment, combining the precision of sequential optimization with the realism of non-sequential validation.

Practical Use Case: AR Coating for Laser Collimators

Consider a laser collimation system designed for biomedical imaging. In OSLO, engineers define AR coatings on lenses and optimize them to reduce losses at 632.8 nm (He-Ne laser line), testing for angle and polarization variations due to tight tolerances.

Then, in TracePro, they simulate the entire system including housing reflections, off-axis laser incidence, and stray light from uncoated edges. The coating performs well optically but shows minor absorption on one element that could affect longevity.

The team refines the coating in OSLO using a different material with lower absorption, retests in TracePro. This dual approach results in a high-efficiency, durable system that meets all performance specifications.

Advanced Applications and Future Considerations

The combination of OSLO and TracePro enables analysis of increasingly sophisticated coating applications.

Machine learning integration is beginning to enhance optimization processes, while improved material databases expand the range of analyzable coating materials. The software platforms continue to develop capabilities for emerging applications in autonomous vehicles, augmented reality, and space-based optical systems.

Advanced optical coating analysis is no longer a luxury—it's a necessity in the age of miniaturized, high-performance optical systems. OSLO and TracePro, when used together, provide a comprehensive toolkit to not only design sophisticated coating stacks but also evaluate how they behave in the real world.

The synergy between sequential and non-sequential analysis approaches ensures that modern optical coatings meet both theoretical performance requirements and real-world operational demands, making these tools indispensable for contemporary optical engineering.